Innovative technology leads new trend in pipe pile production

pipe pile production

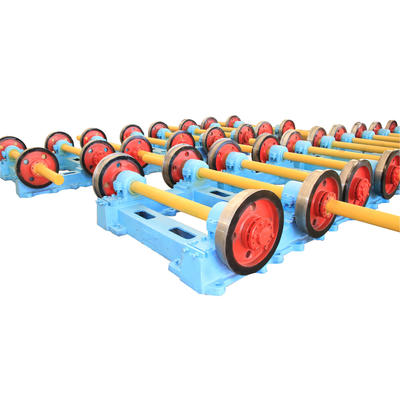

Spinning Machine

In the development of today's construction industry, pipe piles are an important part of foundation projects, and their production quality and efficiency directly affect the stability and progress of the project. With the continuous development of science and technology, pipe pile production equipment is also constantly updated, bringing more efficient and precise production processes to the industry. The latest innovative technology, the Spinning Machine, is leading the new trend in pipe pile production.

The traditional production process of pipe piles requires the use of multiple pieces of equipment and complex operating procedures, which not only results in a long production cycle but is also prone to quality problems. The emergence of rotational molding machines has completely changed this situation. This equipment combines rotational molding technology and advanced automatic control systems to achieve integrated production, greatly improving production efficiency and product quality.

The working principle of the rotational spinning machine is to use the principle of rotational processing to gradually shape the steel plate into the cylindrical shape of the pipe pile through a specific spinning mold while rotating at high speed. The key is to accurately control the rolling speed and spinning pressure of the sheet through an automatic control system while rotating at high speed, ensuring the dimensional accuracy and surface quality of the pipe pile.

Compared with traditional production processes, rotational molding machines have obvious advantages. First of all, the production cycle is greatly shortened, and it only takes a few minutes to complete the production of a pipe pile, which greatly improves production efficiency. Secondly, the high degree of automation in the production process reduces the impact of human factors on product quality and ensures product consistency and stability. Furthermore, the equipment has a simple structure, is easy to operate and maintain, and reduces production costs and labor costs.

In the field of engineering construction, pipe piles are important basic materials, and the requirements for their quality and efficiency are getting higher and higher. As a new generation of pipe pile production equipment, the rotary spinning machine will bring new production models and technical standards to the industry, and promote the development of the pipe pile industry in a more intelligent and efficient direction.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย 한국어

한국어 Svenska

Svenska Malay

Malay বাংলা

বাংলা Dansk

Dansk हिन्दी

हिन्दी Pilipino

Pilipino عربى

عربى Indonesia

Indonesia čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ slovenský

slovenský Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski Српски

Српски Afrikaans

Afrikaans עִברִית

עִברִית Беларус

Беларус lugha ya Kiswahili

lugha ya Kiswahili ជនជាតិខ្មែរ

ជនជាតិខ្មែរ Монгол хэл

Монгол хэл Zulu

Zulu Cebuano

Cebuano Somali

Somali O'zbek

O'zbek հայերեն

հայերեն Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch

Detailed Explanation Of Concrete Production Process

After the concrete is delivered to the construction site, the technical person in charge of the construction party will conduct on-site inspection of the concrete.

Read MoreA Brief Analysis Of The Method Of Testing Cement Strength

Preparation of mortar: Mechanically stir mortar with 450±2g of cement, 1350±5g of standard sand and 225±1g of water in a mixer. First add water to the pot, then add cement, place the pot on the fixed rack and raise it to a fixed position.

Read MoreInnovative Concrete Power Duct Mold Boosts Efficiency in Infrastructure Projects

In the rapidly growing construction sector, the demand for durable and efficient solutions is driving attention to Concrete Power Duct Mold technology. As cities expand and infrastructure upgrades accelerate, the role of specialized molds—especially Precast Concrete Product Mold systems—has become more significant in ensuring quality, safety, and cost-effectiveness.

Read More